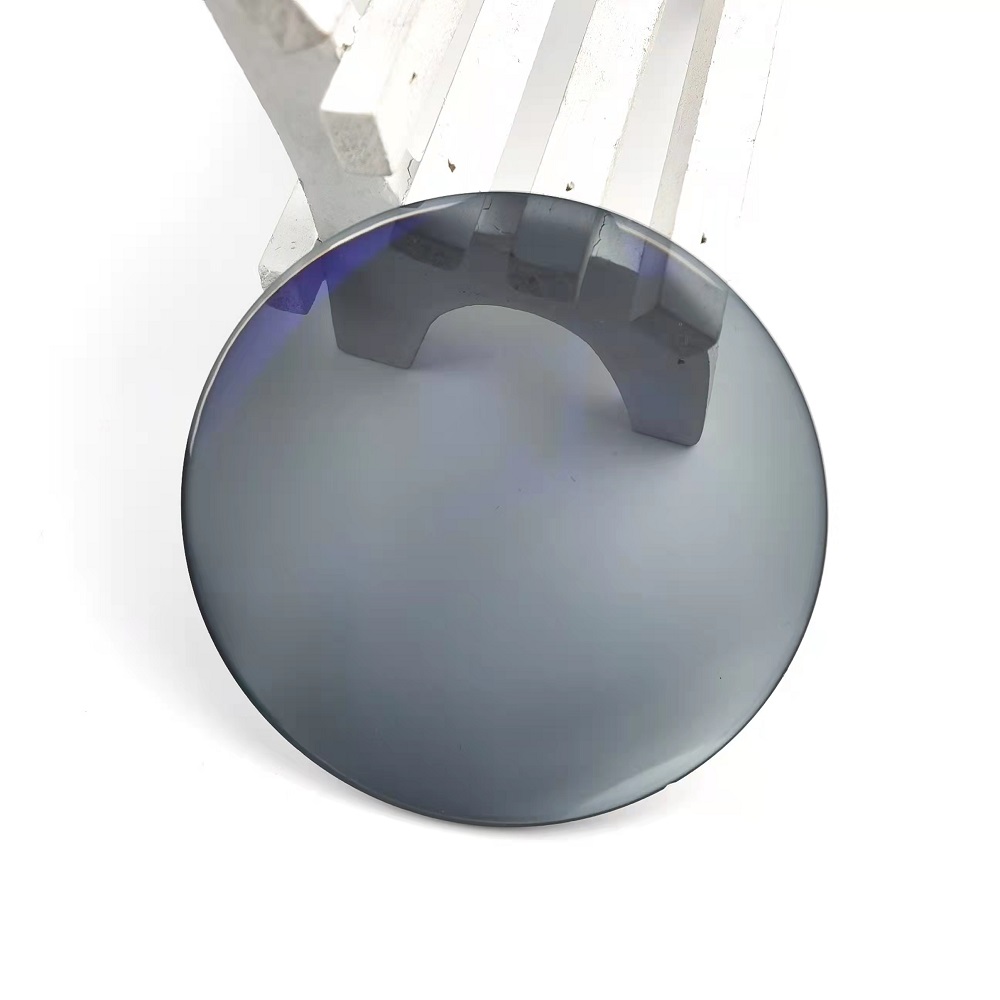

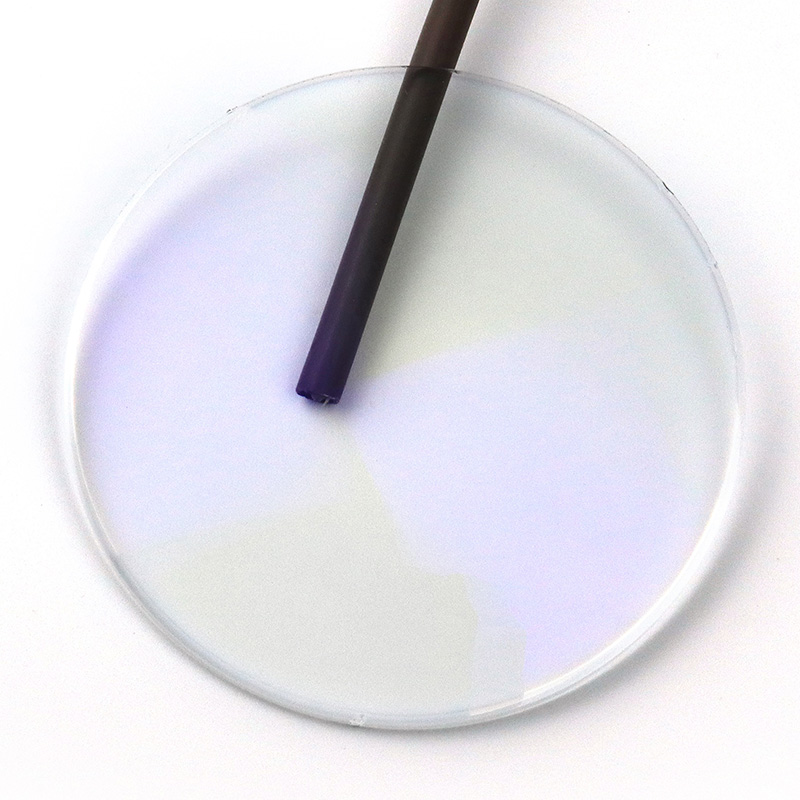

I-SETO 1.60 Ilensi ye-Photochromic SHMC

Ukucaciswa

| 1.60 ilensi yokubona ye-photochromic shmc | |

| Imodeli: | 1.60 ilensi yokubona |

| Indawo Yomsuka: | I-Jiangsu, China |

| Ibhrendi: | SETO |

| Izinto zamalensi: | I-Resin |

| Umbala Wamalensi: | Kucace |

| I-Refractive Index: | 1.60 |

| Ububanzi: | 75/70/65 mm |

| Umsebenzi: | photochromic |

| I-Abbe Value: | 32 |

| I-Gravity ethize: | 1.26 |

| Ukukhetha Kokubamba: | I-HMC/SHMC |

| Umbala wokumboza | Okuhlaza |

| Ibanga lamandla: | Sph:0.00 ~-10.00;+0,25 ~ +6.00;Umjikelezo: 0.00 ~ -4.00 |

Izici Zomkhiqizo

1) Yini i-spin coating?

I-spin coating inqubo esetshenziselwa ukufaka amafilimu amancane afanayo kuma-substrates ayisicaba.Ngokuvamile kusetshenziswa inani elincane lezinto zokumboza enkabeni ye-substrate, okungenzeka ukuthi iphotha ngesivinini esiphansi noma ingajiki nhlobo.I-substrate isuke ijikeleziswa ngesivinini ifike ku-10,000 rpm ukuze isakaze izinto zokumboza ngamandla e-centrifugal.Umshini osetshenziselwa ukuhlanganisa i-spin ubizwa ngokuthi i-spinner coater, noma i-spinner nje.

Ukuzungezisa kuqhutshekwa ngenkathi uketshezi luzungeza emaphethelweni e-substrate, kuze kube yilapho kufinyelelwa ubukhulu obufunekayo befilimu.I-solvent esetshenzisiwe ivame ukuguquguquka, futhi ngesikhathi esifanayo iyahwamuka.Lapho isivinini se-angular sokujikeleza siphezulu, ifilimu iba mncane.Ubukhulu befilimu bubuye buncike ekuboneni nasekugxiliseni kwesixazululo, kanye ne-solvent.[2]Ukuhlaziywa kwethiyori yokuphayona kwe-spin coating kwenziwa ngu-Emslie et al., futhi kuye kwanwetshwa ababhali abaningi abalandelayo (kuhlanganise noWilson et al., [4] abafunde izinga lokusabalala kwe-spin coating; kanye no-Danglad-Flores et al., [5] othole incazelo yendawo yonke yokubikezela ukujiya kwefilimu efakiwe).

I-spin coating isetshenziswa kakhulu ekwenzeni i-microfabrication yezendlalelo ze-oxide ezisebenzayo engilazini noma ku-crystal substrates eyodwa kusetshenziswa izandulela ze-sol-gel, lapho ingasetshenziswa khona ukwakha amafilimu amancane afanayo anobukhulu be-nanoscale.[6]Isetshenziswa kakhulu ku-photolithography, ukufaka izendlalelo ze-photoresist cishe ugqinsi lwe-micrometer engu-1.I-Photoresist ivamise ukuphonswa ngokuphenduka okungama-20 kuye kwangama-80 ngomzuzwana imizuzwana engama-30 kuye kwangama-60.Ibuye isetshenziselwe kabanzi ukwakhiwa kwezakhiwo ze-photonic ezihleliwe ezenziwe ngama-polymers.

Enye inzuzo yokwemboza amafilimu amancane ukufana kokuqina kwefilimu.Ngenxa yokuzilinganisa, ubukhulu abuhlukani ngaphezu kwe-1%.Kodwa-ke, ama-spin coating amafilimu aminyene ama-polymers nama-photoresist angaholela ebuhlalu obukhulu obusemaphethelweni obunomkhawulo wokuhleleka kwawo.

2) Isebenza Kanjani I-Spin Coating?

Le nqubo isebenza ngokulawula ngokucophelela isivinini esihlobene nezakhiwo ezihlukahlukene zezinto zesixazululo.I-viscosity iyinhloko phakathi kwalezi zakhiwo njengoba inquma ukumelana nokugeleza okufanayo, okubalulekile ekufezeni ukubukeka okufanayo kwendawo.I-spin coating ngemuva kwalokho yenziwa phakathi kwebanga lejubane elibanzi kakhulu, ukusuka kancane njengokuphenduka okungama-500 ngomzuzu (rpm) kuya kokufika ku-12,000 rpm - kuye ngokubonakala kwesixazululo.

I-Viscosity akuyona ukuphela kwempahla ebonakalayo enentshisekelo ku-spin coating, noma kunjalo.Ukushuba kobuso kungase futhi kuthinte izici zokugeleza zesixazululo, kuyilapho amaphesenti okuqinile angaba nomthelela ekugqileni kwefilimu emincane edingekayo ukuze kuzuzwe izici ezithile zokusetshenziswa ekugcineni (okungukuthi ukuhamba kukagesi).I-spin coating kamuva yenziwa ngokuqonda okuphelele kwezakhiwo zempahla efanelekile, enenqwaba yemingcele elungisekayo ukuze ivumelane nezici ezihlukile (ukugeleza, i-viscosity, ukumanzisa, njll.).

I-spin coating ingenziwa kusetshenziswa isiqalo esimile noma esiguquguqukayo, ngasinye esingahlelelwa i-acceleration ramping echazwe ngumsebenzisi kanye nesivinini sokujikeleza esihlukahlukene.Kubalulekile futhi ukuvumela izikhathi zokukhipha intuthu kanye nezikhathi zokomisa njengoba ukungangeni kahle komoya kungase kubangele amaphutha okubona kanye nokungafani.Isibonelo: Amaphethini e-Swirl angase abonise ukuthi izinga lokuqeda liphezulu kakhulu isisombululo esithatha isikhathi eside ukuze some.Asikho isixazululo esilingana nosayizi owodwa uma kukhulunywa nge-spin coating, futhi inqubo ngayinye kufanele yenziwe ngendlela ephelele yesisombululo se-substrate nesembozo okukhulunywa ngaso.

3) Ukukhetha Ukugqoka?

Njengo-1.60 Photochromic Lens SHMC, i-super hydrophobic coating iwukuphela kwenketho yokumboza yakho.

I-Super hydrophobic coating iphinde ibize i-crazil coating, ingenza ama-lens angangeni manzi, i-antistatic, i-anti slip kanye nokumelana nowoyela.

Ngokuvamile, i-super hydrophobic coating ingaba khona izinyanga ezingu-6 ~ 12.

Isitifiketi

Imboni Yethu