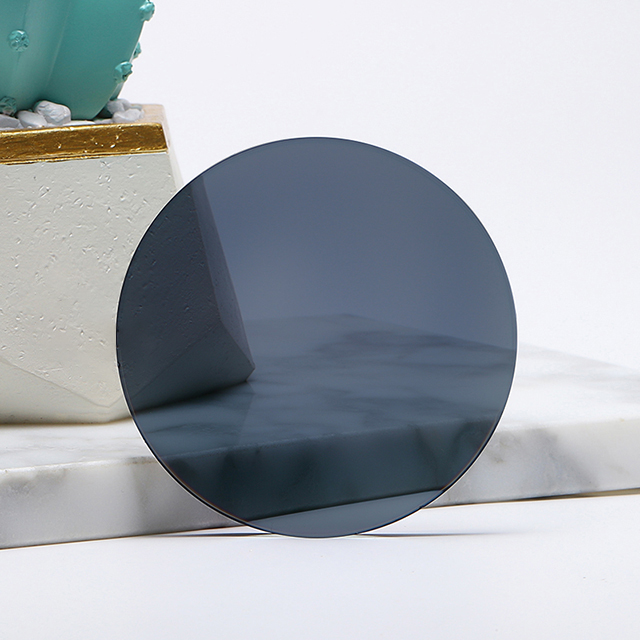

Seto 1.67 PhotoChromic Lens Shmc

Ukucacisa

| 1.67 PhotoChromic shmc lens | |

| Imodeli: | 1.67 Ilensi ye-Optical |

| Indawo yemvelaphi: | Jiangsu, China |

| Brand: | Seto |

| Izinto ze-lens: | -Minzana |

| Umbala welensi: | -Cwebile |

| I-Index Resuactive: | I-1.67 |

| Ububanzi: | 75/70/65 mm |

| Umsebenzi: | I-PhotoChromic |

| Inani le-ABBE: | 32 |

| Ukudonsela phansi okuthile: | 1.35 |

| Ukukhetha okukhokhisa: | HMC / SHMC |

| Umbala we-coating | -Yimpatho |

| Uhla lwamandla: | I-SPH: 0.00 ~ -12.00; +0.25 ~ +6.00; I-CYL: 0.00 ~ -4.00 |

Izici zomkhiqizo

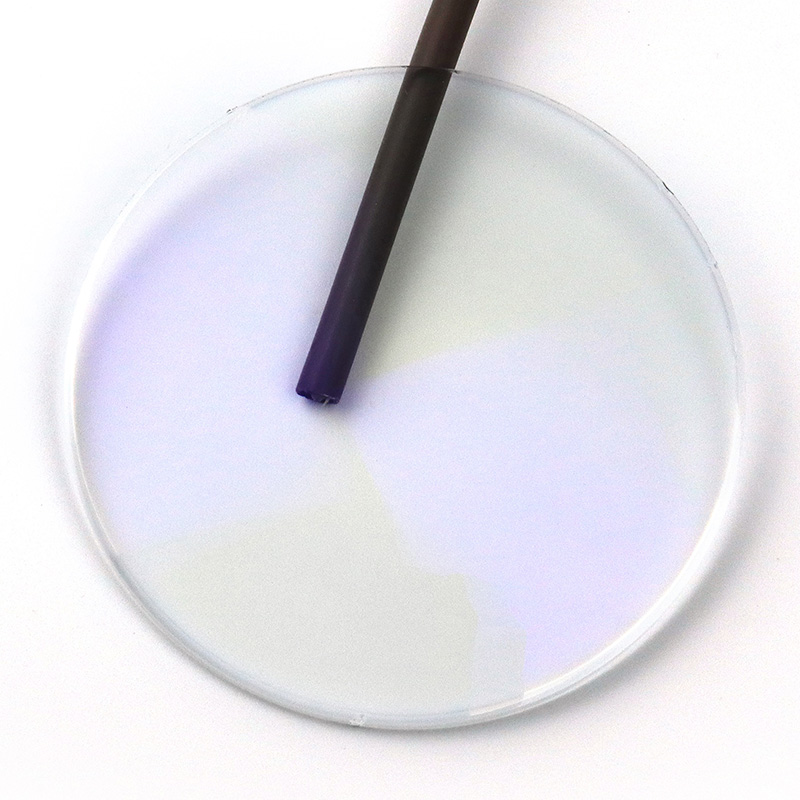

1) Yini i-spin coating?

I-Spin Coating iyinqubo esetshenziselwa ukufaka amafilimu amancane afanayo ezingxenyeni eziphansi. Imvamisa inani elincane lezinto ezihlanganayo lisetshenziswa enkabeni ye-substrate, okuyinto ephotha ngejubane eliphansi noma aliphonswanga nhlobo. I-substrate ijikelezwa ngejubane elifinyelela ku-10,000 RPM ukusakaza impahla enamanani ngama-centrifugal Force. Umshini osetshenziselwe i-Spin Coating ubizwe ngokuthi yi-spin coater, noma umane nje.

Ukujikeleza kuyaqhubeka ngenkathi uketshezi luphuma emaphethelweni e-substrate, kuze kube yilapho ubukhulu befilimu butholiwe. I-solvent esetshenzisiwe ivame ukuguquguquka, futhi ngasikhathi sinye. Lapho uphakamisa ijubane le-angular lokuxubha, elincanyana ifilimu. Ubukhulu befilimu buya ngokuya ngokubonakala kanye nokuhlushwa kwesixazululo, kanye ne-solvent. Ukuhlaziywa kwe-feenoling theoretical of Spin Coating kwenziwa ngu-Emslie et al., Futhi kunwetshwe ngababhali abaningi abalandelayo (kufaka phakathi iWilson et al. Incazelo ye-Universal ukubikezela ubukhulu befilimu obufakiwe).

I-Spin Coating isetshenziswa kabanzi ku-microfabrication of functional oxide izingqimba ezisebenza ngengilazi noma ezingxenyeni ezizodwa ze-crystal zisebenzisa amafilimu we-sol-gel, lapho kungasetshenziswa khona ukudala amafilimu amancanyana afanayo abukhulu be-nanoscale. [6] Isetshenziswa kakhulu ku-photolithography, ukufaka izingqimba ze-Photoresist mayelana ne-1 micrometre obukhulu. I-Photoresist imvamisa ihlelwe ngezinguquko ezingama-20 kuye ku-80 ngomzuzwana imizuzu engama-30 kuye kwangama-60. Iphinde isetshenziselwe kabanzi ngenhlawulo yezinhlaka zePlanethi zenziwe ngama-polymers.

Inzuzo eyodwa yokuphoqa amafilimu amancanyana ahlanganisiwe ukufana kobukhulu befilimu. Ngenxa yokuzenzisa, ubukhulu bokuzihlanganisa abufani ngaphezu kwe-1%. Kodwa-ke, amafilimu akhudlwana ama-spin amafilimu ama-polymers kanye nama-photoresist angaholela ekutheni ubuhlalu obukhulu obukhulu bokuhlelwa kwalona okubangela okungokomzimba.

2.Chofoza kanye nomgomo we-PhotoChromic Lens

I-PhotoChromic Lens Ngokusho kwezingxenye ze-Lens Discoloration ihlukaniswe ngama-lens we-photochromic (okubizwa ngokuthi "ukuguqulwa kwesisekelo") kanye ne-membrance ungqimba lwelensi (okubizwa ngokuthi "ukuguqulwa kwamafilimu" izinhlobo ezimbili.

Ilensi ye-substrate PhotoChromic ifakwa into yamakhemikhali ye-halide yesiliva e-lens substrate. Ngokuphendula kwe-ionic kwe-halide yesiliva, kubunjiwe kube yisiliva kanye ne-halide ukuhlanganisa imibala lens ngaphansi kokukhuthaza okukhanyayo. Ngemuva kokuthi ukukhanya kuba buthaka, kuhlanganiswe neheheli yesiliva ukuze umbala ube lula. Le ndlela ivame ukusetshenziselwa i-Glass Photochroimc Lens.

I-Film Change lens iphathwa ngokukhethekile kwinqubo ye-lens yokuhlanganisa. Isibonelo, amakhompiyutha we-Spiroopyran asetshenziselwa ukunamathela kwesivinini esikhulu ebusweni belensi. Ngokuka ukuqina kokukhanya okukhanyayo nokukhanya kwe-ultraviolet, isakhiwo samangqamuzana uqobo singashintshwa futhi sifinyelele umphumela wokudlula noma ukuvimba ukukhanya.

3. Ukukhetha okukhokhiseni?

Njengoba i-1.67 PhotoChromic Lens, i-Super Hydrophobic Coatis ukuphela kokukhethwa kukho okunama-coating ngakho.

I-Super Hydrophobic Coating ibuye igama elithi Coatil Coatil, angenza ama-lenses angangeni manzi, antistatic, anti slip kanye nokumelana kawoyela.

Ngokuvamile, ukuhlanganiswa kwe-super hydrophobic kungaba khona ama-6 ~ 12 izinyanga.

Ukufakazela ngencwadi

Ifektri yethu